The Essence of Modular Construction

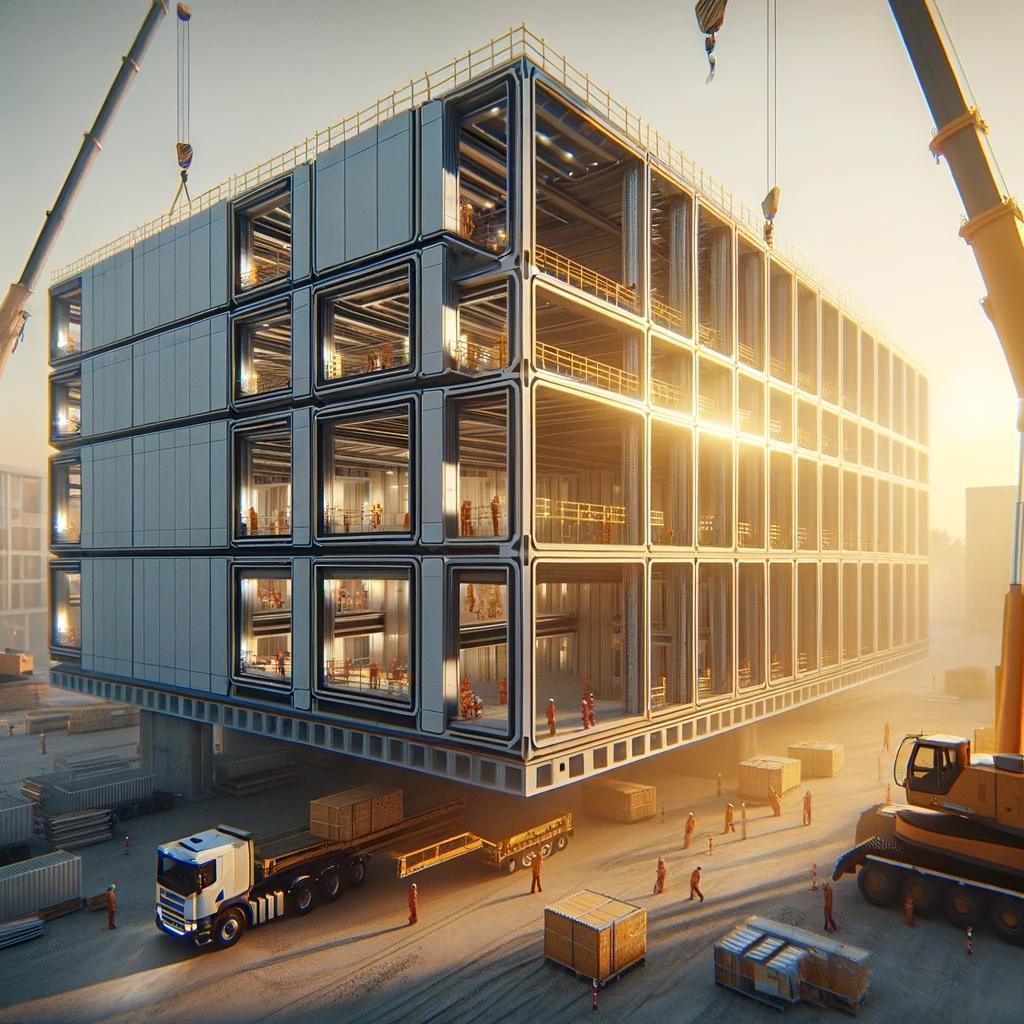

Modular construction involves manufacturing standardized components of a building in an off-site factory and then assembling them on-site. This method contrasts sharply with traditional construction, where the majority of work, from laying the foundation to the finishing touches, occurs at the primary construction site. The controlled environment of a factory setting significantly reduces the chances of weather-related delays and enhances quality control, making this method a beacon of efficiency and reliability.

Why Prefabrication Marks a Paradigm Shift?

Prefabrication is closely related to modular construction but includes a broader range of elements made off-site, such as pre-wired electrical panels or pre-plumbed kitchen and bathroom pods. These components, when integrated into construction projects, significantly cut down on-site activity, which minimizes construction waste and reduces the overall carbon footprint of buildings.

A pivotal aspect of prefabrication is its impact on labor allocation. With a significant portion of work shifted off-site, the need for skilled labor on-site diminishes, which is a crucial benefit in regions experiencing skilled labor shortages. Furthermore, prefabrication offers a safer working environment, as most labor is conducted in controlled factory settings, reducing the risks associated with on-site construction.

Streamlining Processes and Maintaining Tight Schedules

One of the most significant advantages of modular construction and prefabrication is the ability to maintain tight schedules. Projects can proceed without delay in factory settings, irrespective of external conditions such as bad weather. Moreover, because parts of the construction occur simultaneously off-site and on-site, the total build time can be reduced by as much as 50% compared to traditional methods.

The predictability in timing helps not only in faster project completion but also in better cost management. With fewer variables to contend with (like weather delays or scheduling conflicts), project managers can allocate resources more efficiently, potentially lowering overall costs.

Challenges and Considerations

Despite its benefits, modular construction and prefabrication face challenges. Transportation logistics can be complex, as large prefabricated modules need to be shipped to the construction site, which requires careful planning to avoid damage and ensure timely delivery. There is also the challenge of public perception and industry adaptation; traditional builders and buyers may be hesitant to adopt new methods, preferring the familiarity of conventional construction techniques.

The Future Landscape of Construction

The future of construction likely holds a more integrated approach where traditional and modular methods coexist, leveraging the strengths of each according to project needs. Innovations in technology, such as 3D printing and advanced robotics, are set to further enhance modular construction and prefabrication. These technologies promise even greater precision and efficiency, potentially reducing costs and construction times dramatically.

As urban areas continue to expand and the demand for more sustainable building solutions grows, the methods of modular construction and prefabrication stand out as beacons of innovation. They offer not just speed and efficiency but also a way to tackle some of the most pressing challenges of modern construction, including labor shortages, safety concerns, and environmental impact.

Key Takeaways for Industry Stakeholders

For developers and project managers, the key to successfully implementing modular and prefabricated elements lies in meticulous planning and embracing a forward-thinking mindset. Early integration of these methodologies in the planning stages can greatly enhance the feasibility and efficiency of projects.

Clients and end-users, meanwhile, can benefit from the faster completion rates and potentially lower costs, not to mention the environmental benefits of reduced waste and lower emissions.

As we move forward, the construction industry's landscape will continue to evolve, but one thing remains clear: modular construction and prefabrication are not just temporary trends, but pivotal elements in the future of building. As such, embracing these innovations can lead to more sustainable, efficient, and adaptable construction practices that will meet the needs of tomorrow’s world.

Recent Statistics

The modular construction market has been experiencing significant growth, with various projections estimating continued expansion through 2030. The global market size of modular construction was approximately $84.48 billion in 2023 and is expected to reach about $131.58 billion by 2030, growing at a compound annual growth rate (CAGR) of 6.5% during the forecast period. This growth is driven by factors such as the need for cost savings, speed in construction, and sustainable building practices that reduce waste.

Steel is one of the preferred materials in modular construction due to its durability, strength, and fire resistance. It's particularly favored for multi-story buildings like apartments, hotels, and offices because it can be prefabricated off-site, enhancing construction speed and quality while minimizing waste. Steel's recyclability also contributes to its popularity as an eco-friendly construction option.

In terms of applications, the residential segment is one of the largest in modular construction, but there is also significant growth in the commercial sector, which includes the construction of offices, retail spaces, and hospitality structures. The commercial sector is particularly appealing due to its cost-effectiveness and the flexibility it offers in quickly establishing operational business spaces.

Regionally, Asia-Pacific is poised for the fastest growth in the modular construction market, largely due to rising infrastructure investments and a growing focus on sustainable building practices. Meanwhile, Europe and North America also show strong market presence, with Europe leading in market share due to high levels of technology adoption and supportive government initiatives.

This ongoing shift towards modular construction is supported by continuous advancements in technology and increasing emphasis on sustainability, positioning modular methods as crucial for the future of construction.

Frequently Asked Questions

What exactly are modular construction and prefabrication, and how are they transforming the construction industry?

Modular construction involves producing entire sections of buildings in a factory setting, which are then transported to the construction site for assembly. Prefabrication extends this concept to include the manufacturing of ready-to-install components like electrical systems and plumbing. These methods are transforming the industry by dramatically reducing construction time, enhancing quality control, and decreasing waste.

What growth trends are we seeing in the modular construction market?

The modular construction market has been experiencing robust growth. According to industry reports, it's projected to increase from $85.4 billion in 2020 to $107.9 billion by 2025, with a CAGR of 5.7%. This growth is driven by the efficiency and cost-effectiveness of modular construction techniques.

Can you quantify the benefits of prefabrication in terms of time and cost savings?

Certainly! Prefabrication can reduce overall construction time by approximately 30% and costs by about 20%. Additionally, it minimizes construction waste by up to 90%, aligning with more sustainable building practices.

What are the main challenges facing the adoption of modular construction and prefabrication?

The major challenges include logistical complexities related to transporting large prefabricated sections and the industry’s slow cultural shift towards new technologies. There's a need for increased coordination and planning to manage these logistical tasks effectively.

How are emerging technologies like 3D printing and robotics impacting these construction methods?

Emerging technologies are further refining these methods by enhancing precision and reducing labor costs. Robotics, for instance, supports more accurate and efficient production of modular components, while 3D printing offers new possibilities in creating complex, customized building elements more sustainably.

With the rising demand for sustainable building solutions, how do modular construction and prefabrication fit into this trend?

These methods are inherently more sustainable. They reduce the environmental impact of construction through minimized on-site disturbances, decreased waste, and more efficient use of materials. They're becoming crucial in meeting global sustainability targets in the construction sector.

What should industry stakeholders focus on to effectively integrate modular construction and prefabrication into their projects?

Stakeholders should focus on the early integration of these techniques in the project planning stages, invest in workforce training to adapt to these new methods, and develop robust logistics strategies to handle the transportation and assembly of prefabricated modules. Embracing these methods can lead to significant strategic advantages in the competitive construction market.

The Role of Online Catalogs and Company Directories in Modular Construction and Prefabrication.

In the rapidly evolving field of modular construction and prefabrication, the accessibility and dissemination of information are crucial. Online catalogs and company directories serve as vital resources, enhancing visibility, fostering connections, and driving the adoption of these innovative construction methods. Here’s how these tools are shaping the industry:

Streamlining Access to Innovative Solutions.

Facilitating Product Discovery: Online catalogs are comprehensive platforms that allow manufacturers to showcase their prefabricated products and modular solutions. These digital catalogs make it easier for contractors, developers, and architects to explore various options, compare different solutions, and make informed decisions based on the specifications and capabilities of the materials and technologies available.

Enhancing Visibility of New Technologies.

As new technologies and materials emerge, particularly those enhancing modular construction and prefabrication, online catalogs update regularly to reflect these innovations. This constant renewal helps industry professionals stay abreast of the latest advancements, from 3D printed components to automated modular systems.

Fostering Industry Connections.

Building B2B Relationships: Company directories play a crucial role in connecting different stakeholders within the modular construction and prefabrication industry. These directories make it easier for businesses to find and engage with suppliers, manufacturers, and service providers who specialize in modular and prefabricated construction. This is essential for fostering collaborations that can lead to more efficient project executions.

Promoting Specialization.

With prefabrication and modular construction requiring specialized skills and technologies, company directories help highlight firms that have specific expertise. Whether it’s a company skilled in producing modular hotel rooms or an architectural firm specializing in designing prefabricated homes, these directories help match projects with the appropriate experts.

Driving Industry Standards and Compliance.

Ensuring Quality and Compliance: Online catalogs often include detailed information about the compliance and standards adherence of products, which is critical in construction where safety and durability are paramount. Access to this information helps industry professionals ensure that the components they choose meet the required standards and are suitable for their specific project needs.

Updating Regulatory Changes.

As building codes and regulations evolve, particularly around sustainable practices and safety, online catalogs and directories provide a platform for disseminating these updates. By staying informed through these resources, companies can adjust their practices and product offerings to comply with new regulations, thus avoiding costly penalties and project delays.

The integration of online catalogs and company directories into the modular construction and prefabrication industry represents a critical development in how information is exchanged and how business transactions are conducted. These tools not only streamline the process of finding and comparing products and services but also play a significant role in ensuring that industry standards are met and that the latest technologies are readily accessible. As the industry continues to grow, the importance of these digital resources will only increase, becoming a fundamental component in the ecosystem of modern construction.

Ready to peel back the curtain on the next big thing in the architectural arena? Imagine stepping into a future where the buildings come together like a scene from a sci-fi flick—welcome to the modular construction revolution!

Thank you for reading,

We use cookies

We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. Privacy Policy.